Choose us!

-

Latest technology

During the production of our products we are using the latest technology.

-

Continuous innovation

We are following the trends on our field and we aspire to introduce latest novelties.

-

Quick production process

Using the latest technological processes makes it possible for us to quickly serve our customers.

-

Continuous training

Our company is pays special attention to the training of its employees.

-

Efficient services

We are working in a multi-shift pattern, to ensure the quick and efficient services for our customers.

-

High quality

Our products meet the highest standards on the market.

-

Food industry

Confectionery, bakery, spice packaging, vegetable and fruit processing, meat industry

-

Chemical industry

Cosmetics, household products, hygienic products

-

Technology

Electronics, agriculture, machinery, plastic products

-

General usage

Textiles, household products, stationary products, gardening, hygienic products

Favorite products

All products

Pointed bag

Pointed bag are packaging containers that can be used widely for packaging products like sweets, seeds and smaller vegetables. In the course of the production bags can be made into blocks, either by heat, or with metal spikes or plastic plugs to be used onThürlings packaging machines, which is always determined by the type of packaging (manual or mechanical packaging).

The unique shape makes this packaging highly spectacular and eye-catching.

GENERAL properties:

-

unique appearance

-

high quality

-

easy pack design

FIELDS OF USE:

-

confectionery industry

-

vegetable and fruitprocessing

-

bakery industry

Potted sleeve

Trapezoid bags are ideal for packaging potted plants and herbs. The glossy material is excellent for colour printing, which gives the product a pleasing appearance.

With our expertise and highly developedmeans of production we provide high quality bags for the automated packaging of cut flowers and potted plants.

GENERAL properties:

-

unique appearancemagas

-

high quality

-

easy pack design

Fields of USE:

-

flower production

-

herb production

LAMINATED POUCH

During the production of laminated bags several foil types are combined. Thanks to their outstanding colour printability and complex confection possibilities, these bags provide an exclusive appearance to the packaged products.

It is especially recommended for premium category products, be it products that require cooling or products that are vacuum packaged or modified atmosphere packaged (MAP).

GENERAL characteristics:

-

exclusive appearance

-

glossy or matte surface

-

aesthetical

-

colour printable

-

strong four-side seal

FIELDS OF USE:

-

confectionery industry

-

meat industry

-

baking industry

-

spice packaging

-

fruit and vegetable processing

-

coffee packaging

-

household products

-

cosmetic products

MICROPERFORATED BAGS

During microperforation, small holes are created on the surface of the foil, thus, allowing the air to get through to the packaged product. This solution is used especially for the packaging of baked goods or vegetables.

During the procedure, the microperforation of the polypropylene foil (BOPP, CPP) is made with the help of heated pins, while the perforation of the polyethylene foils is made with cold pins.

GENERAL CHARACTERISTICS:

-

aesthetical

-

glossy

-

colour printable

-

breathable

FIELDS OF USE:

-

baking industry

-

fruit and vegetable packaging

-

confectionery industry

-

clothing industry

POLYETHYLENE BAGS

Polyethylene is the most widely used packaging material. Thanks to its cost-effectiveness, it is the most popular packaging material. It can be easily printed and coloured. It allows a maximum adaptability to buyer needs, given its multi-faceted confectioning possibility.

During production -- according to consumer needs -- the properties of the foil are enhanced by adding certain additives, e.g. antistatic, anti-slip, roughener.

MAIN FIELDS OF USE:

-

baking industry

-

confectionery industry

-

meat industry

-

stationery

-

agriculture

-

engineering

-

chemical industry

-

plastics industry

-

electronics industry

POLYPROPYLENE BAGS

It is the most popular and most cost-effective packaging method of dry products. This packaging material provides an aesthetic appearance to products. It is the second most popular packaging material besides polyethylene. Its multi-faceted use makes it possible to flexibly adapt it to consumer needs.

It is a customer-inviting and cost-effective packaging solution, while also protecting the products from environmental intrusions. It can be used on its own or for the creation of laminates. Its two main types are the BOPP and CPP.

GENERAL CHARACTERISTICS:

-

cold-resistant

-

it can be sterilised

-

it can be metalized

-

it can be pasteurised

-

it can be laminated

FIELDS OF USE:

-

baking industry

-

confectionery industry

-

fruit and vegetable packaging

-

plastics industry

-

clothing industry

-

stationery

WICKET BAGS

We recommend this bag to our partners who have own automatic and semi-automatic packaging machines, because it is perfect for industrial packaging. Thanks to features that facilitate their opening, the wicket bags allow a quick and exact automatized packaging.

The outstanding quality, 8 colour flexo printing technology enhances the product`s appealing, customer-inviting appearance.

MAIN FIELDS OF USE:

-

Baking industry, pre-packed breads

-

Fish products

-

Pre-packed fruit and vegetables

-

Gardening products

-

Hygiene products

-

Cosmetic products

-

Frozen products

-

Technology

-

FLEXO PRINTING MACHINE

FLEXO PRINTING MACHINE

Flexo printing is one of the youngest and most dynamically developing branches of rotogravure printing, where the flexible printing form, which is required for printing, is fixed to a variety of circular cylinders.

-

-

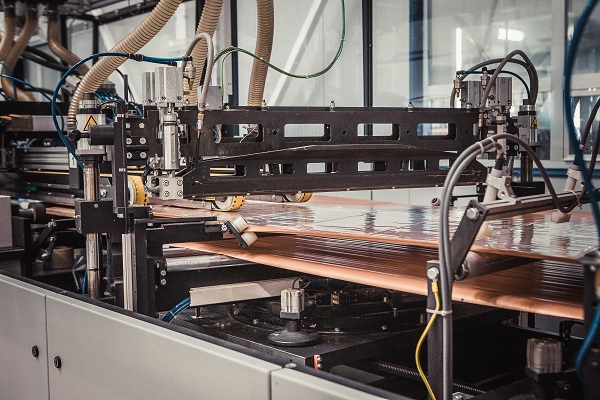

TRAPEZOID BAG PRODUCING MACHINE

TRAPEZOID BAG PRODUCING MACHINE

Special trapezoid bag producing machine is also suitable for manufacturing custom sizes.

-

Address

9600 Sárvár, Ikervári u. 40.

-

Phone numbers

+36 95 994 0294

+36 95 325 867

+36 95 520 142

-

Fax

+36 95 520 144

-

Email

info@szemipack.hu

info@szemipack.com

kereskedelem@szemipack.hu

sales@szemipack.com

-

Webpage

www.szemipack.hu